Have you ever considered the complex decision making, physics and even chemistry involved in de-icing and anti-icing an aircraft?

Sounds boring? Well in fact the difference between de-icing and not de-icing is a matter of life or death.

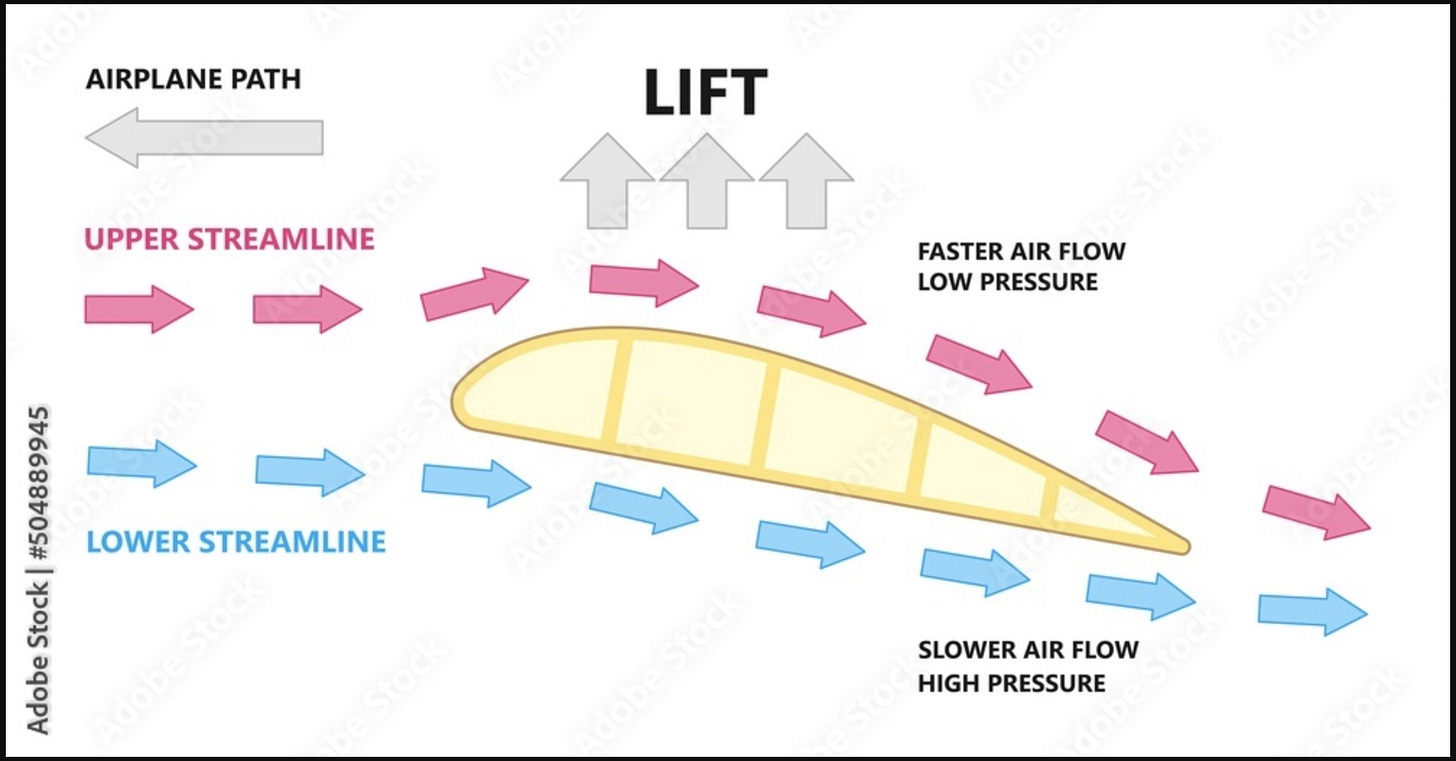

Firstly the physics- Aerodynamic Airflow

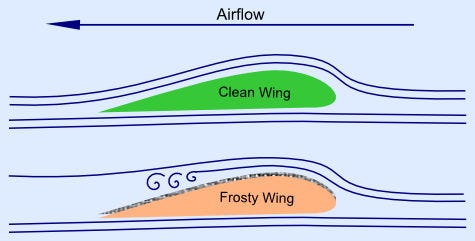

Effects of ice and snow on airflow

As this diagram shows, any frost, ice or even bugs and dirt can effect the airflow over a wing and consequently change the lift of the wing away from the carefully tested design of the wing.

As we will discover with a study of Air Florida Flight 90 ( but there are many other examples), changing the aerodynamic airflow can lead to aeroplane control surface behaviours that can ultimately become unexpected pitch, roll or bank, stall or a crash.

Today’s aviation safety and that of tomorrow rests on lessons learnt from past incidents, accidents, mistakes and near misses.

Part of learning from previous incidents through accident reports, incident reports and having Human Factors training helps identify potential problems as they occur and prevent a series of failures snowballing into an incident.

That is why many airlines have a “Just Culture” system to encourage honest reporting of problems, mistakes and errors without jeopardising employment. In fact the act of NOT reporting and subsequently being found to have swept a problem under the carpet can impose greater consequences for the crew or staff involved.

And so with an understanding of threats and errors and how they can be managed best when an airline operation is running with least possible stress (i.e. enough frontline staff and resources in operational and engineering areas ) that I can introduce an incident which has fundamentally informed aviation’s understanding of the threat of even minimal icing on an aircraft’s airframe.

Air Florida Flight 90

We can then learn from an incident in 1982 where Air Florida Flight 90, a Boeing 737-200 took off and with a minute had clipped a bridge and crashed into the Potomac River, Washington.

Here is an excellent accident investigation video- MentourPilot

As with any incident or accident, there was not just one factor involved in the chain of threats and errors for Air Florida Flight 90.

Management of de-icing and allowing the icing to re-accumulate instead of returning for another treatment. i.e. Allowing time pressure to override safe decisions

Hold Over Times ( HOT - I will explain in a minute)

Non adherance to a Boeing Safety Notice advising 737 airline operators that use of thrust reversers on taxi can cause non uniform coverage of icing on an airframe, especially build up on leading edge of the wings.

This results in the airflow becoming disrupted over the wing and in the case of the 737 it was known to cause a high nose attitude after takeoff from the runway which can cause a stall. Crews were advised if this should happen to correct nose attitude by lowering the nose.

Engine anti-ice not switched to the ON position

Coming from a Florida-based operator, crew not used to cold weather operations and the insidious temperature and pressure changes that can indicate a problem with icing conditions. Pilots are now widely and specifically trained in “Cold Weather Operations”.

Captain using hot air from DC9 taxiing in front to clear ice build up from the 737. Again, non uniform build up or melting of icing and affecting aerodynamic stability of the 737

Icing on an aircraft- what does it look like?

The chemistry - Various Types of Anti-Ice and De-Icing fluids

Type I

Is used as a de-icing fluid to remove icing from the aircraft surfaces. It can further used as an anti-icing fluid to prevent icing build up on aircraft surfaces. It is a mild anti-ice fluid for temperatures near freezing or just below freezing but doesn’t provide durable protection.

Type IV

Is used as an anti-ice only so de-icing needs to occur first. This is used for much lower temperatures and heavier snowfall intensity but at a significantly higher cost to the aircraft operator.

The choice of fluid is a trade off between length of protection and cost. The skill of the Anti-Ice operator is to balance the two competing factors.

Hold Over Times

Hold Over Times (HOT) commence at the start of application of the second ( in the case of Type I only, the commencement of that application) or anti-ice fluid to the start of takeoff roll.

HOT stipulates the time of protection provided conditions ( i.e snowfall intensity and temperature) remain within specified limits.

This requires that the crew monitor both snowfall intensity and temperature throughout the taxi until takeoff roll commences.

Real World Video- Vancouver 2022

So here is the fun bit. In Vancouver (YVR) International Airport, British Colombia, Canada in December 2022 I experienced de-icing and anti-icing first hand on two occasions.

Coming from a warmer climate there is little in the way of de-icing treatment required in our country except in some cities in the midst of winter and then it is for icing not snowy conditions.

In Vancouver I was able to see the captain’s preparation the afternoon before the flight, brushing up on icing procedures and steps to follow if treatment required. It came to pass that this preparation was indeed needed to quickly and competently organise deicing and anti icing so that “Iceman” and his crew could do their jobs and we could get on our way safely. Website for Aeromag who de-ice for Vancouver and many other airports.

I videoed these anti icing and deicing processes and share one with you here:

As you can now appreciate, a bit of a delay on the ground to ensure the aerodynamic surfaces of the aeroplane are not contaminated is vitally important. To not do it because there is pressure to get going can result in catastrophe. That is where a captain’s ability to prioritise tasks and make the tough calls even though they may be unpopular is paramount.